Many aspects of the University of Texas at San Antonio’s Roadrunner Athletics Center of Excellence (RACE) made our team proud before, during, and after construction. The University of Texas at San Antonio’s Roadrunner Athletics Center of Excellence (RACE) recently won the 2021 Associated General Contractors of America Texas Building Branch Outstanding Construction Awards. UTSA’s Roadrunner Athletics Center of Excellence (RACE) also notably won a Merit Award from Engineering News Record Texas and Louisiana.

UTSA’s RACE celebrates the growth of the UTSA Athletics program, a new 95,000 SF two-story facility dedicated to student-athletic training, wellness, academic excellence, campus spirit, and recruitment.

The facility consists of day-to-day all-sport team spaces, including locker rooms, equipment room, sports medicine, coaches offices, team meeting rooms, weight room, athletic administration offices, and academic space. The front foyer features a “Hall of Fame Alumni” lobby, the team meeting rooms have stadium seating, the weight room features a nutrition bar, and there are several student-athlete lounges as well as study areas.

Outside, two practice fields are emblazoned with the signature Roadrunner mascot at the center, one synthetic turf, and one grass.

The project kicked off at the start of the COVID-19 pandemic in March 2020. Despite a world of challenges, we turned over the project on time and with great fanfare.

On August 4, 2021, UTSA Athletics moved into their new home. The first football training camp kicked off the following week. Roadrunner Football went on to achieve a record-breaking year for the 2021 Football Season.

RACE, a state-of-the-art Athletics Facility, supports the UTSA Athletics program’s continued success and evolution, and we’re proud to be a part of that legacy.

Difficulty In Construction

Some of the challenges on this project include:

- Erosion Control during early project phases

- Acclimating to challenges initiated by the COVID-19 pandemic, including communication, material and manpower shortages, and other unknowns

- Texas Snow-pocalype in February 2021

- Second wave of COVID-19 and third round Stimulus Checks in Spring 2021

- Satisfying stringent testing requirements, often beyond what was specified

- Immense interest in the project from donors, the press, and public

- Industry-wide long lead times; national trucking and port issues

Preparing the Site & Early Procurement

Erosion Control Necessary

The RACE project site is located on 10.8 acres of land near the Southwest corner of the University’s Main Campus. Our first order of business was to level off the hilly terrain-demo the parking lot on “Rattle Snake” hill, remove trees into a ravine, mill down the hill, and then bring up the ravine with fill from on-site material until balanced.

The project team employed a series of erosion and dust control methods to minimize the dust, including spraying the dirt stockpiles and exterior perimeters with water. However, the UTSA Lap Pool was right next door. Despite our efforts, dust flowed down and collected in the pool water. We coordinated with the staff to clean the pool and make it right.

We anticipated the students being frustrated to lose the parking lot (we began work during Spring Break of 2020), but the campus remained eerily silent the week after. The university shut down classes, marking the start of the COVID-19 Pandemic on the project. It was an interesting way to start the project. We had no idea what would lay ahead.

Early Procurement Push

The Joeris pre-construction team escalated the buyout and procurement process timeline to ensure the trades locked in all pricing and the submittal process could start quickly. After receiving Notice to Proceed, this aggressive push helped overcome early material procurement issues.

Hydro Pools

In this early submittal process, ordering the hydro pools eliminated the need for an entire tilt-wall panel installed out of sequence due to the size clearance needed to roll the pools into the building. These custom pools are large hot, cold, and plunge pools used for sports medicine and physical therapy sessions. This material needed to be ordered early due to the long lead time and unloading into the building. Joeris communicated with the Roadrunner Foundation to order and bill for this material early.

COVID-19 and Other Acts of God

A unique aspect of the RACE project was that it kicked off in March of 2020 and faced the world’s challenges regarding Covid-19. Then, in February of 2021, new factors would come into play from which material and manpower availability would never recover during the project duration.

The Initial Wave Affects Communication

Nowadays, zoom meetings are ordinary, but during the early stages of Covid, acclimating to this new way of communication had its challenges. The infrastructure to make digital group meetings easier, like cameras and blue tooth speakers, was not in place. Masks made it challenging to understand, and decisions made easier by in-person collaboration still had to be made.

Sample Approvals

Reviewing samples was especially difficult – sample parties didn’t work over zoom. We ultimately had to mail samples to the various stakeholders. Creating consensus and getting approval was hard to achieve, especially when ordering materials in a timely fashion was more important than ever. We made it work!

Locating Utilities

While the campus was shut down, maintenance staff and coordinators were unavailable to assist with campus knowledge. Joeris coordinated with our engineering consultants and trades to successfully locate existing on-campus utilities (water, gas, power, irrigation, communication) despite outdated documents and no visible markings as guides.

This coordination allowed site demo, utility work, and new work around the construction limits to be installed in proper sequence. UTSA and UT Security were all aware of construction activities.

The Second Wave, the Storm, and the Stimulus

Despite the pandemic and materials starting to become harder to come by, in January of 2021, the project team was feeling confident—the RACE structure was going up, the field installs were starting. We returned project savings to the owner. We were ahead of schedule. Then, fate threw us some more curveballs from which material and manpower levels would never recover during the project duration.

In February of 2021, a Texas winter storm left nearly 4.5 million Texans without power and/or in subfreezing temperatures for several days. We shut down the project for a week. The pandemic infection rate across the United States picked up for a second wave. The snow week affected manpower across all trades for numerous weeks after that. Materials were delayed, and this caused schedule phasing issues requiring multiple strategies to recover.

On Easter weekend, the project team pushed through working on Good Friday, trying to recover the schedule due to manpower shortages. That same week, the government released the third round of Covid-19 aid as stimulus checks. The week after Easter, only 1/3 of the trade staff scheduled to work showed up. Joeris and numerous trade partners implemented working night shifts and weekends to recover.

From April until August of 2021, the project became a blur. Staff changes on major trades. Material delays. Schedule recovery. Ultimately, this story ends in success, but our heroes had to first overcome every obstacle that came their way to get there. That makes this project a marker of this Joeris project team’s tenacity and willingness to see this project through and with the quality the UTSA student-athletes and staff deserve.

Material Challenges

Numerous material challenges were outside of the norm. As early as September 2020, we started to see steel lead times grow (12 – 14 weeks), and trucking shortages became more apparent.

Tracking materials also grew more challenging. The weight room flooring came from China through the port of Canada, and although it eventually arrived, it was impossible for us to really know where it was in the shipping process: Was it stuck on a ship? In customs? Who knows?! Additionally, all imported materials had to be tested before they came in.

Wood doors became an industry-wide issue right in the middle of the project going from a typical 6-8 week lead time to 14+ week lead time with minimal notice from the manufacturer.

Inspired by our experience with the weight room flooring, we worked with the design team on material substitutions, switching from foreign to domestic tile (from Italy to Florida.)

Joists

Joists also presented a material challenge. We began receiving the joists when we figured out and confirmed that the joist layout specs differed from our drawings with the fabricator. During this time, we were on the phone two or three times a day to coordinate the proper install plans. Three iterations of shop drawings later, we were able to move forward. Luckily, we caught the conflict early enough that only two or three joists had to be changed, and the schedule was not delayed.

UNUSUAL CONSTRUCTION TECHNIQUES

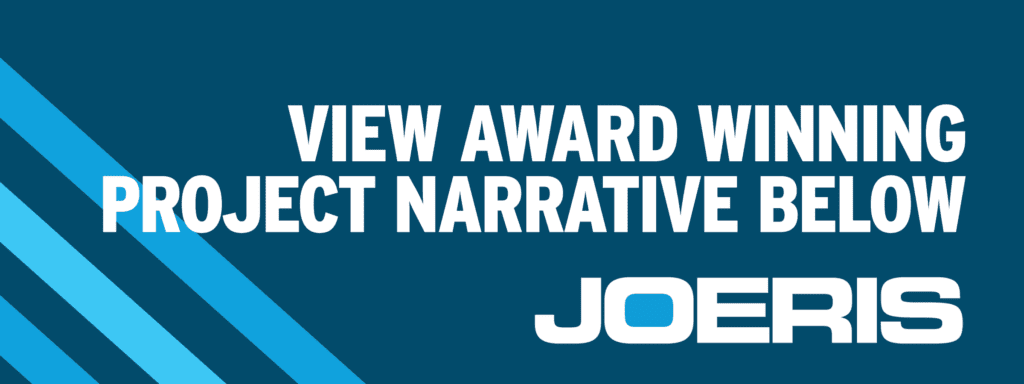

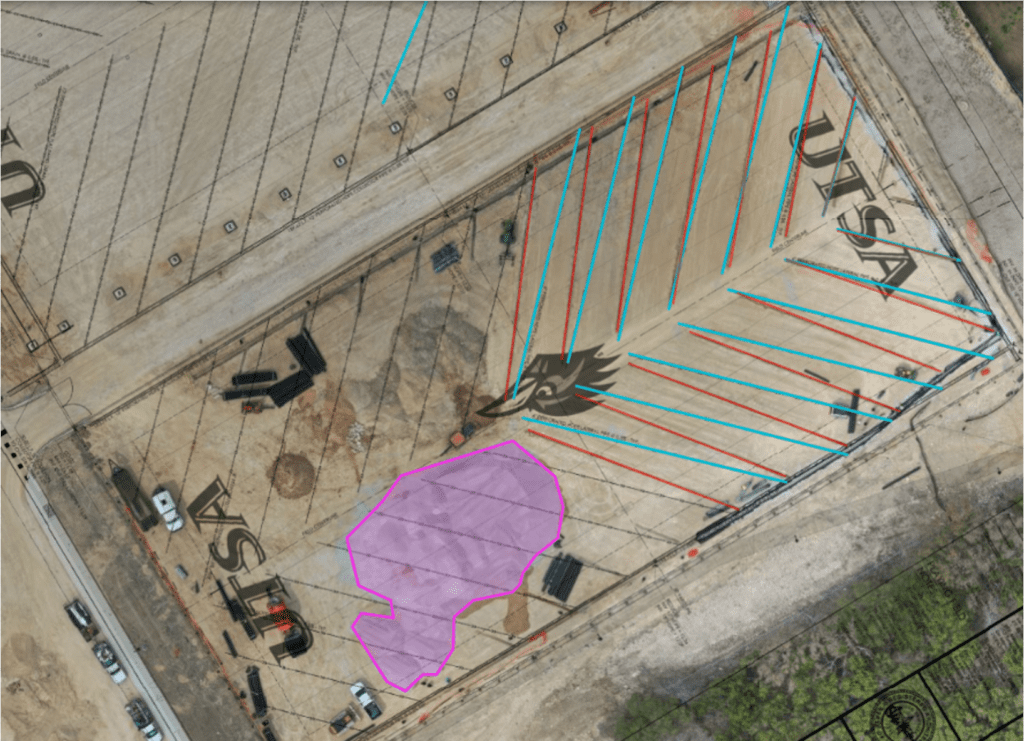

Drones as Quality Control Vehicles

The Joeris project team was concerned about perforated drainage’s spacing and installation angle on the practice fields. We utilized drone deploy, a drone mapping software, to verify the spacing with imported civil overlay and annotation tools. Joeris elevated our own quality control techniques by using a tool typically used for documentation in this new way.

The overlay demonstrated a variance between the work completed and spec’d. We identified the problem with 25% of the work done instead of completing both fields incorrectly. The visual analysis allowed the team to clearly communicate the issue to the trade partners, putting the ball in their court to ensure timely correction and limiting the time lost.

Stringent Testing Techniques

This project was subject to stringent testing requirements that often went beyond what was specified. This ultimately created situations of mismatched expectations. Our project superintendent went above and beyond to accommodate the needs created by the inspections’ stringency and frequency, which included additional meetings, documentation, and research time.

Technology Power-Up for Documentation

A specific demonstration of the intensity of the inspection process on this project can be reflected in the amount of server space needed for the photo documentation. Joeris utilizes PlanGrid for our in-the-field document management. A typical project within PlanGrid will house hundreds of documentation photos and videos totaling around five to ten GBs. For RACE, we had to upgrade our PlanGrid cloud size for this project to 25 GBs to accommodate the photos and videos that numbered in the thousands.

Field Install

The level tolerance on the turf practice field was tighter than any we’ve seen before and had to meet the design standards of a notoriously picky sports field consultant. Surveys were conducted by a third party in a grid pattern of 25 ft on center with a tolerance of ¼ inch and submitted to an engineer in Kansas City, Missouri. This quality control process took several attempts to pass, making it all the sweeter when we received the green light.

Project Managers Turned Professional Tour Guides

There was immense interest in the project from donors, the press, future student-athletes, and the public from start to finish. The project team gave tours as frequently as Covid-19 protocols would allow, and each time, they gave the tour to the best of their ability, never knowing who was there to give philanthropically, write a story, or try to pick which school was right for them.

This was Joeris’ first project with the Roadrunner Foundation, a non-profit donor group of community leaders and alumni, including Gene Dawson, President of Pape-Dawson Engineers. The foundation was integral to the rallying cry and push to advance the UTSA Athletics program and coordinate the funding required to make this crowning campus gem a reality.

FINAL APPEARANCE AND QUALITY OF THE FINISHED PRODUCT

RACE is a celebration of the UTSA Athletics program. It’s a recruitment tool, an all-in-one community space for student-athletes to train, learn, and grow together. The new state-of-the-art space allows the athletes to envision their future while finding the best platform in the present—and that platform is in the front foyer—a photo-op stage for high school athletes to celebrate their decision to be a roadrunner on signing day.

The evolution of higher education sports facilities helps student-athletes evolve into stronger players, produce more cohesive teams, and elevate the game.

The onsite rehabilitation and sports medicine areas are vital to keeping the team strong. But not in the way you might think— receiving treatment while watching a film reduces time apart from the group. Injured student-athletes stay close, utilizing the facilities within the same building as the rest of the team practices or work out.

Behind the scenes, university staff care for and store the uniforms, helmets, and gear in the equipment management and laundry facilities. Student-athletes retrieve their personal kit from double-sided cubbies that work like lockers from the athletes’ side.

Each position coach has their own viewing room with state-of-the-art AV and stadium seating. Tennis, golf, soccer, and other athletics have unique office spaces.

The football locker room is top-class, marked by the Roadrunner’s team colors – orange and navy blue. Internal mechanical HVAC is integrated into each locker to pull the smell and dry. Overhead, the central light fixture features the smiling face of the team’s mascot.

When the strength coach first saw the weight room in all its glory, his reaction was priceless when he saw the lights and heard the sound coming through the speakers. Student-athletes posted endless reaction videos on their social channels, excited to share their new facility with the world.

The RACE facility is even more critical because there isn’t a stadium to use as a shining beacon for student-athletes considering UTSA as their school of choice. The facility’s purpose is to drive hype for the student-athletes who get to train there. That purpose was achieved.

TIMELINESS OF COMPLETION

The project kicked off at the start of the Covid-19 pandemic in March 2020. Despite all the challenges that came our way, we turned over the project to UTSA on time and with great fanfare.

On August 4, 2021, UTSA Athletics moved into their new home. The first football training camp kicked off the following week. Roadrunner Football went on to achieve a record-breaking year that season.

New RACE Facility lends to Record- Breaking Year for Roadrunner Football

The 2021 football season was a record-breaking year for Roadrunner Football – they won their first conference championship in the history of the young program, recorded their highest win total (12 games), and received their first national ranking in the program history.

In a testament to the continued growth and elevation of the UTSA football program, UTSA received and accepted an invitation to join the American Athletic Conference.

At this writing, the UTSA Athletics program is only 10 years old, and the growth and evolution achieved in 2021 alone are remarkable. Joeris is honored to have played a role in building a state-of-the-art athletics facility that supports the program’s continued success and progression.