Alamo Heights ISD Natatorium

Project Features, Team Support, and Transformation

Project Narrative by Joeris General Contractors

Estimated reading time: 11 minutes

The San Antonio Chapter of the Associated General Contractors of America recently recognized and awarded Joeris General Contractor’s work on Alamo Heights Independent School District’s New Natatorium for the local 2021 AGC-TBB Outstanding Construction Awards.

At Joeris, our mission is to transform people and places. The Joeris project team passionately lived into the Joeris mission as they constructed the new natatorium.

Project Features

Alamo Heights ISD’s New Natatorium has an array of features that provided unique and incredible aspects, cultivated from the project team visiting numerous other natatoriums to derive inspiration and the proper research.

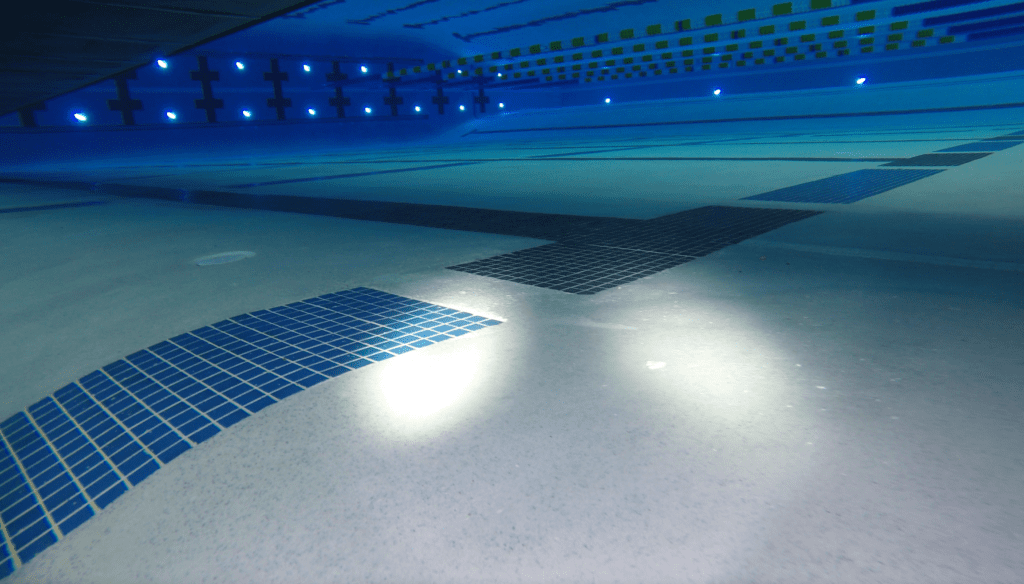

The new natatorium features a 39-meter-long pool crafted to serve the public as well as to inspire students and athletes. Completed in January 2021, the facility is Joeris’ first natatorium. The quality of the work leaves an impressionable mark for future educational aquatic facilities.

The Process

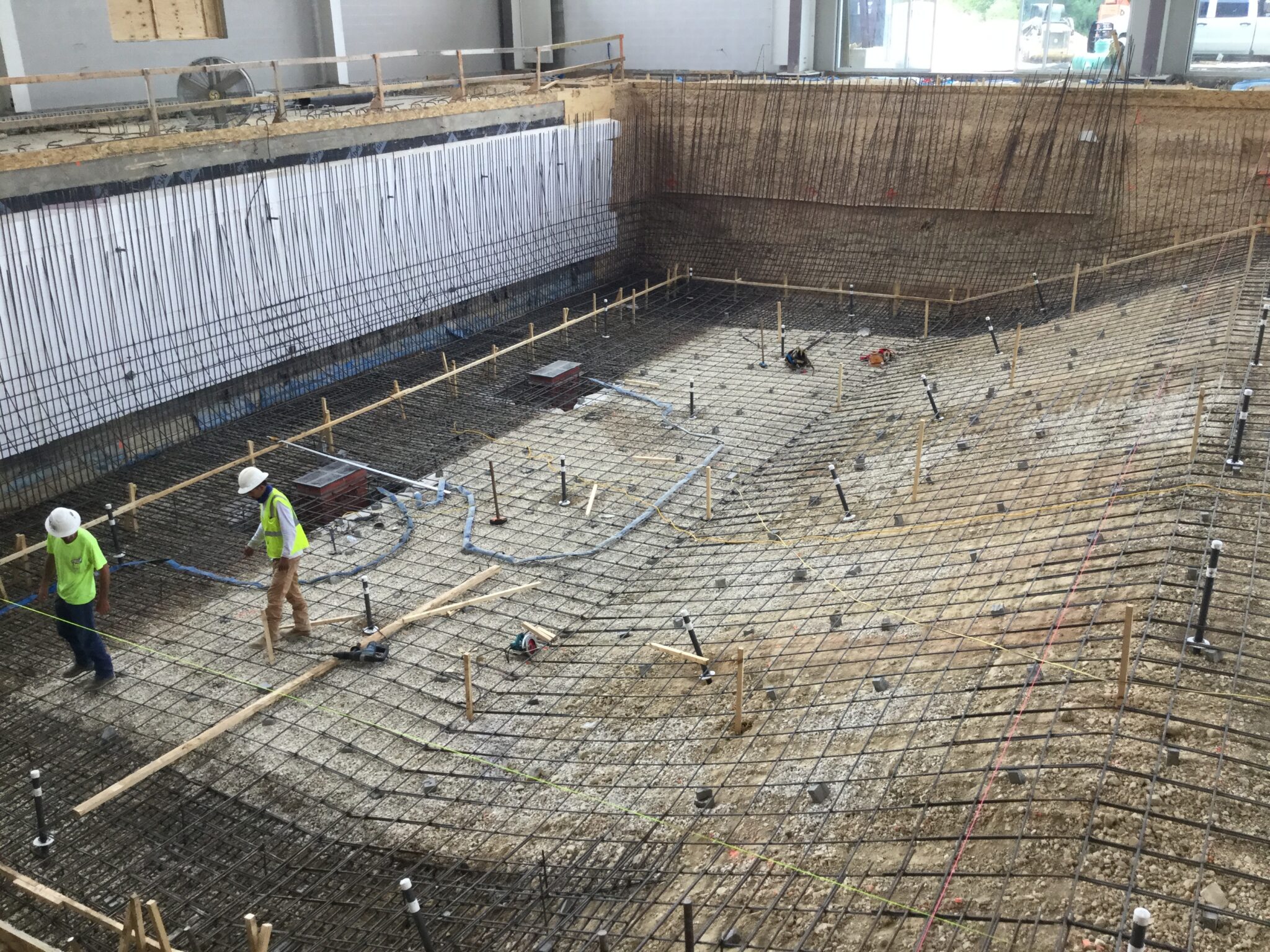

The project team took impressive consideration in the proper planning and sequencing of the project scope of work. This thought process involved planning the integration of the pre-engineered metal building (PEMB) structure, with the structural steel-framed building components. Extensive planning went into the timing of the actual pool construction, which was housed inside the PEMB, with the locker rooms and lobby being housed inside the structural steel-framed component.

Timing the design and fabrication of the structural components was key to facilitating a seamless installation. The PEMB portion of the building was constructed first, followed by the erection of the structural steel-framed building. Both followed by the erection of the structural steel-framed building. Both scopes were strategically performed by the same trade partner for ease of coordination and collaboration, which gave our team a considerable advantage. The project team sequenced the work to allow continuous flow through the two structures.

Before pool construction, the above ceiling MEP components and interior finishes were completed in the PEMB structure. This gave safe access to the overhead ceiling space and ensured that all trade partners had adequate timing to complete their work. The pool deck was completed in the final stage, and then the bulkhead was installed.

Movable Bulkhead

The bulkhead prompted multiple opportunities for the team to engage in collaborative efforts due to the nature of the bulkhead designs. This bulkhead was designed as a one-piece unit, which weighed over 16,000 lbs, over 81 feet in length, over 6 feet wide, and about 5 feet tall. The unit is designed to arrive fully assembled and effortlessly floated into the pool’s deep end. This specific scenario posed multiple considerations, as access to the deep end of the pool was limited due to the location of the chiller yard and the positioning of the detention pond. Our project team handled this situation with innovation and skill.

The project team conducted 3D simulations of potential access routes for the bulkhead entry and positioning until they found the perfect solution, which would allow proper maneuvering of the bulkhead to its final location.

Our bulkhead positioning plan included leaving out a section of exterior wall between two columns. From there, the bulkhead traveled into the building and down the south side of the pool deck, where it carefully made a 90-degree turn over the basement structure and then positioned itself on the east end of the pool deck and was lowered into place.

The placement was a perfect fit, as illustrated in the 3D visual model, thanks to the innovation and dedication of the project team.

Location

The project team took a proactive approach to enact Joeris’ Good Neighbor Policy. The natatorium location posed several challenges due to its logistic placement on the existing Alamo Heights ISD Robbins Academy campus and its proximity to a residential neighborhood. We also faced the challenge of working ahead to be aware of the small site, the existing tennis courts on-site, power lines, as well as retention and detention ponds.

Unusual Construction Techniques

Structural Steel

The team took time and consideration was taken in the sequencing of structural steel painting. The epoxy coating of the structure was a key component in the prevention of rusting in the aquatic environment. Due to the positioning of structural components, portions of the erected structure would be unaccessible, leading to rust deposits after the warranty period ended. The team’s dedication to providing AHISD with a quality project for years to come motivated their efforts to coordinate the coating of key structural components as they arrived on site. The project team constructed an on-site paint booth where structural steel members could be properly coated before erection.

Sequencing

A unique feature of this building was fiberglass doors and frames to withstand the harsh environment of a pool. The timing of the installation of these doors and frames was critical since any damage done to the fiberglass coating could not be repaired in the field, requiring a complete frame replacement. Considering the long lead times and high cost of these specialty items, consideration had to be taken in the timing and sequencing of this work and protecting this finished product from adjacent construction activities.

The Skudo Mat

Sometimes unusual construction techniques aren’t all that complicated. One of the quality considerations at the natatorium was to protect the polished concrete floors in the lobby. We knew this floor would be one of the first aspects people would notice when they walked into the natatorium. With this in mind, we utilized a Skudo mat and placed it down to protect the finished floors. Some maintenance was still required to replace damaged mats, but this simple protection technique minimized the rework.

GoPro Dive

Proactive measures were taken to ensure the quality of construction throughout the project. One of the more creative measures included a scuba diving superintendent with a GoPro camera. The superintendent documented the proper placement of the bulkhead, completed punch list items, and retrieved some rock debris in the process. In addition to scuba diving, the project superintendent creatively constructed a magnetic device used to extract screws that had inadvertently made their way into the pool. Daily pool walks became an end-of-the-day activity and elevated the potential for rust deposits on the pool surface.

Proactive Approach, Community Led

The team for the new natatorium consistently provided new ways to improve the project. A good team dynamic is vital in construction as it brings forth positive collaboration and an overall extraordinary outcome.

The project team was passionate about supporting the academic programs at Alamo Heights ISD. Some of that support came in more non-traditional forms. When the project team was invited to support fundraising efforts by participating in a 5K, the team ran to the occasion sporting their Alamo Heights ISD swag.

One of our project team members used to swim at the old natatorium. They mentioned how special it was to work on a project in the community they grew up in and watch it drastically transform into an incredible space. The team fully supported each other and others in a way that showed the integrity our company has pride in.

Joeris understands the importance of small details. The project team went above and beyond when considering such. In one instance, project team members polished brass covers at the pool deck to ensure a pristine visual appearance for the first swim meet. Dedication to the final touches is something this team strived toward daily.

The team wanted to build the new facility in the best way possible – especially since this was our first natatorium. Our team’s passion for constructing an award-winning structure for AHISD motivated them to pursue unconventional means of education. The team wanted to go about building the new facility in a way that embraced collaborative workflow sequences and facilitated productivity through lean leadership principles. As part of the team’s facilitation of continuous learning, multiple natatoriums were visited, facility managers interviewed, and the pool project manager was consulted. This allowed the team to derive inspiration for future workflow and take a deep dive into the lessons learned at the visited facilities.

Final Appearance and Quality of the Finished Product

“Cool Pool”

The impact the new natatorium has had on the public has been incredible. Within a month of the natatorium officially being open, the TYR Pro Series Athletes and Tokyo Olympic Hopefuls trained in the facility. A few of the athletes that trained in the natatorium, Katie Ledecky, Caleb Dressel, and Michael Andrew, qualified and swam for the 2021 Summer Tokyo Olympics. Ledecky, Dressel, and Andrew all returned to the United States with Gold medals; all of them are eying Paris’ Olympics in 2024 as their next target.

Students and locals have been making great use of the natatorium more recently, as there are many classes provided. The Alamo Heights ISD students have benefited from the new natatorium in the accessibility for training, swim meets, tournaments, rehabilitation/physical therapy, and recreational use. Veterans have also made use of the natatorium from the classes provided by different organizations.

Timeliness of Completion

The project was released and ordered in 2018 when we first won the Alamo Heights ISD 2017 Bond Program. Work on the new Alamo Heights ISD Natatorium started in October 2019. Originally planned to be completed in December 2020, this deadline was pushed back to January 2021 – primarily due to the bulkhead being delivered later than expected.

When the facility was opened in late February of 2021, we visited to see how the natatorium was operating, as well as how everyone was perceiving the changes. The athletes visiting for the TYR Pro Series were some of the first to use the new natatorium and viewed it in high regard as they raved about loving the facility. A signed plaque hangs in the facility’s lobby, commemorating their practice session.

The Associated General Contractors of America Texas Building Branch is submitting Joeris General Contractor’s work on Alamo Heights Independent School District’s New Natatorium for the state 2021 AGC-TBB Outstanding Construction Awards.

Related Projects

Did you know the RK Group’s new headquarters sits across the lake from the Red Berry Mansion? And guess what? We built that, too!

Bexar County Courthouse Restorations

These lessons learned on the Bexar County Courthouse’s historic renovation made us who we are today as a Texas General Contractor, transforming people and places.